Support during the process-oriented implementation of optimisation potentials in the Austrian marshalling yards of Linz and Vienna

Based on a previous international benchmarking with comparable marshalling yards for rail freight transport, BSL Transportation conducted an analysis regarding the economic efficiency, speed and safety on two marshalling yards in Austria. Compared with their best competitors, both marshalling yards have shown a huge optimisation potential, in particular in regards to personnel efficiency. Therefore we focused on the analysis of the overall efficiency of all relevant operational groups.

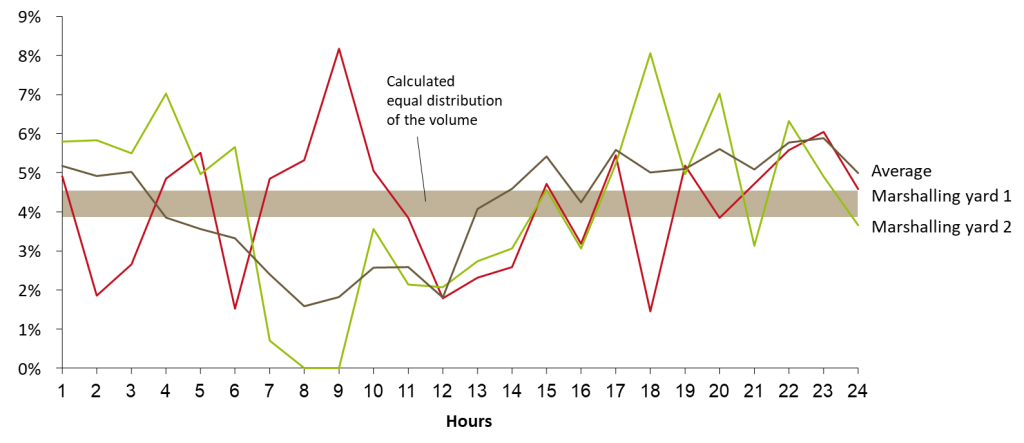

All required project steps were summarised in four work packages. Firstly, we collected all information on the existing processes regarding content, personnel and duration. Then target times and unproductive times were analysed and evaluated. The detailed analysis included all sub-divisions of the marshalling yard like incoming and outgoing traffic and took specific framework conditions into consideration, e.g. varying hourly, daily and weekly volumes:

Figure 1: Hourly volumes per marshalling yard

Based on international best practices in rail freight transport and local framework conditions of our client’s rail freight company, target processes for both marshalling yards were derived and documented as a next step. The drafting of the requirements for the implementation of measures was based on the documentation of flow charts and process attributes.

In cooperation with the management in charge, BSL developed all necessary measures in work package 3. These measures were discussed with all parties involved and were then structured in work package 4, in order to determine actual steps and responsibilities and to develop an implementation plan. Here, we supported our client during their first stage of implementation. In addition, BSL developed an Excel tool to better control the processes and to review the achievement of targets.

Due to the high complexity of the operational processes and structures in marshalling yards for rail freight transport and numerous approaches for optimisation, we supported our client in regards to controlling, conception and implementation of measures.

As a result, for each identified productivity issue we have developed measures which were implemented in close cooperation with the management executives on site.

23. May 2019